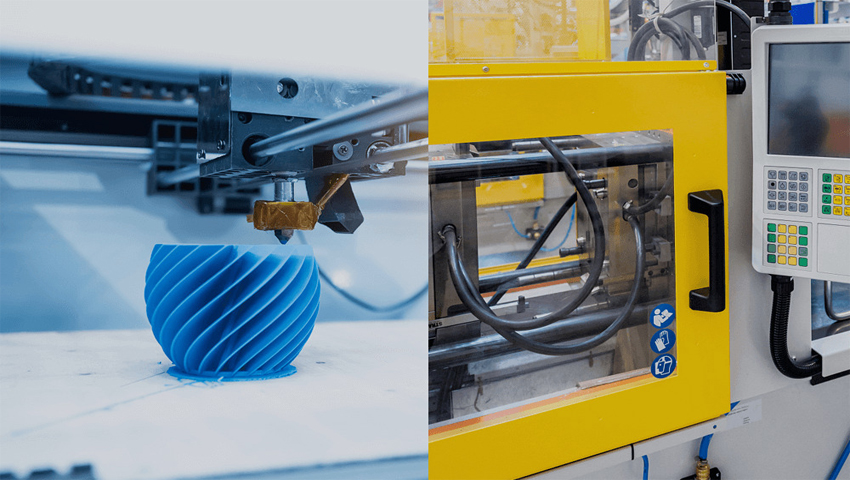

In a notable advancement, 3D printing technology is being employed for applications involving UVA (Ultraviolet A) LED wavelengths, marking a significant stride in the realm of light-based technologies.

Researchers and innovators are leveraging the versatility of 3D printing to create intricate structures and components tailored for UVA LED applications. The UVA wavelength falls within the range of 365 A 405 nm, and its utilization spans various fields, including photopolymerization, UV curing, and fluorescence excitation.

One of the key advantages of 3D printing in conjunction with UVA LED is the precision with which complex structures can be fabricated. This synergy opens up new possibilities for manufacturing customized optical components, lenses, and devices optimized for UVA light emission. Industries such as medicine, electronics, and materials science are particularly poised to benefit from this convergence.

Moreover, the integration of 3D printing and UVA LED technology offers enhanced flexibility in the design and production of prototypes and specialized equipment. This combination not only streamlines the manufacturing process but also facilitates rapid prototyping, allowing for quicker iterations and advancements in research and development.

The versatility of 3D printing allows for the creation of intricate geometries that can manipulate and control UVA light in novel ways. This capability holds promise for applications in fields such as fluorescence microscopy, UV-based sensing, and advanced manufacturing processes that require precise control over UVA light exposure.

As this interdisciplinary collaboration between 3D printing and UVA LED technology continues to evolve, it is expected to unlock new dimensions of innovation, pushing the boundaries of what is possible in fields where precise control of UVA wavelengths is paramount. The intersection of these two technologies represents a promising avenue for future advancements in diverse industries and research endeavors.

LED vorticoso da 1000-1750nm

LED vorticoso da 1000-1750nm