In a pioneering development within the automotive industry, Infrared (IR) LED light sources are spearheading defect detection applications, enhancing the precision and reliability of quality assurance processes. This case study delves into a specific application scenario where IR LED light beads have been successfully employed for defect detection in automotive components.

Application Scenario: Defect Detection in Automotive Assemblies

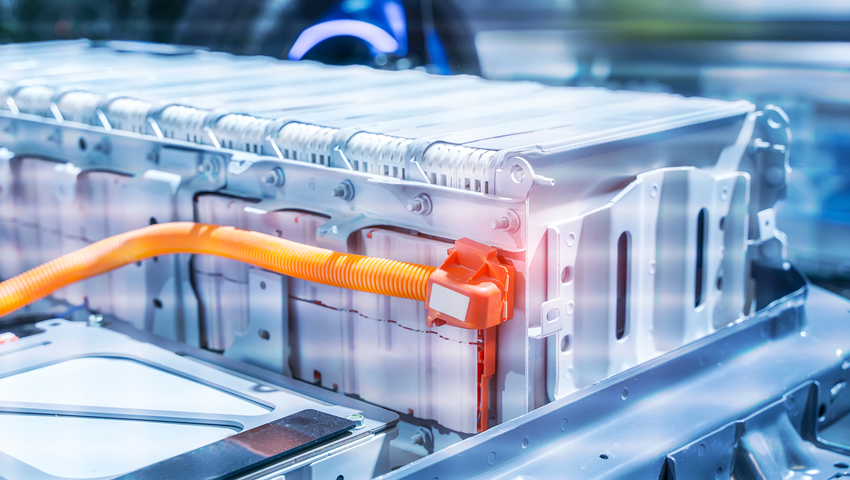

Background: An automotive manufacturing facility sought to elevate the efficiency of their defect detection process during the production of critical components, such as engine parts and electronic modules. Traditional inspection methods faced challenges in identifying subtle defects, necessitating a more advanced solution.

Solution: Infrared LED Defect Detection System The facility integrated an Infrared LED defect detection system into their quality control line. Infrared LEDs, with wavelengths ranging beyond the visible spectrum, were chosen for their ability to penetrate surfaces and reveal hidden defects that might not be apparent under visible light.

Key Features and Outcomes:

Penetration and Visibility:

- Infrared LEDs facilitated the penetration of materials, allowing inspectors to identify defects beneath surfaces that were not visible with conventional lighting.

Surface Anomaly Detection:

- The defect detection system, powered by IR LED light beads, excelled in identifying surface anomalies, such as scratches, dents, or paint imperfections, contributing to an enhanced cosmetic inspection process.

Material Integrity Assessment:

- IR LEDs were particularly effective in assessing the integrity of materials like plastics and rubber, where defects may not be immediately visible. This comprehensive material inspection improved the overall quality of the components.

Non-Destructive Testing:

- The non-destructive nature of the IR LED defect detection system ensured that inspections could be conducted without causing damage to the components, preserving their structural integrity for use in the final product.

Real-Time Feedback and Traceability:

- The system provided real-time feedback to the production line, enabling immediate corrective actions. Additionally, the defect detection system contributed to traceability efforts by recording inspection results for each component.

Enhanced Production Efficiency:

- The integration of IR LED defect detection streamlined the inspection process, reducing false negatives and positives. This led to increased production efficiency as fewer components required rework or were deemed unfit for use.

Conclusion: The successful implementation of Infrared LED light beads in defect detection within the automotive manufacturing process demonstrates a significant advancement in quality assurance. By leveraging the unique properties of IR light, the facility achieved a higher level of precision in identifying defects, contributing to the production of high-quality automotive components. This case serves as a testament to the transformative impact of Infrared LED technology in the pursuit of excellence in automotive manufacturing.

Shenzhen Yingfeng Opto-Electronic Co., Ltd.

Shenzhen Yingfeng Opto-Electronic Co., Ltd.